Introduction

Risk-Based Inspection (RBI) and Non-Intrusive Inspections (NII) are gaining popularity in the oil & gas industry. Many owner-users are trying to justify application of these advanced integrity management practices from a cost savings standpoint. RBI and NII are designed to achieve significant cost savings and risk mitigation benefits over a piece of equipment’s lifetime in the long term (e.g. through greater reliability and inspection optimization). It is important to strategically consider new NDE technologies to obtain data of sufficient confidence to satisfy the requirements of the risk model. Mixtures of qualitative and quantitative approaches and output need to be weighed in terms of benefit to the risk model. Such a mixture should raise and not lower the confidence in the model’s prediction of the damage state of the equipment. Unfortunately, some practitioners are taking more credit than deserved for the effectiveness of past inspections, practices and NDE technologies. This can produce inaccurate estimates of equipment integrity and cause RBI programs to look ineffective when it was not the fault of the RBI algorithms. This is what we have encountered in Australia’s O&G industry, but we suspect it is a global problem. In this article, we plan to summarize what is involved in a practical RBI/NII application, and describe our current view of a consistent system of pressure equipment integrity inspections, with common pitfalls eliminated.

Risk-based Inspection vs Time-based Inspections

Pressure vessels, heat exchangers, storage tanks, and pressure piping must be inspected regularly to control the risk of equipment failure. The regulatory framework in most places requires owner-users to monitor the integrity of their equipment as a matter of public safety. Therefore, pressure equipment integrity risks should be strategically addressed to avoid Health and Safety, Financial, and Environmental consequences associated with loss of containment.

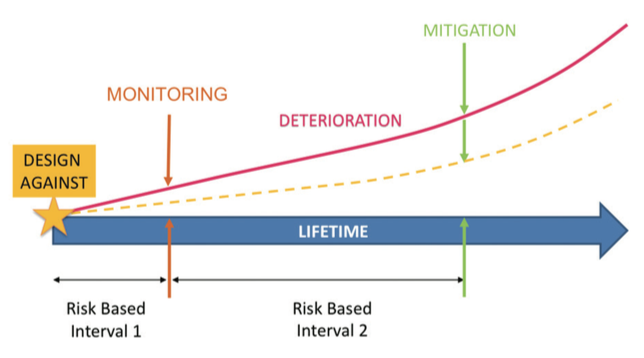

The primary goal of in-service inspections is to provide owner-users with accurate information on the extent of asset degradation and the rate at which it is degrading. (Figure 1)

As opposed to rotating equipment (pumps, turbines, gearboxes, etc.), static equipment pressure envelopes are usually not “maintainable” and not redundant within a facility. As a result, regular internal condition monitoring (such as internal inspections) is required to avoid plant shutdowns, which can cost millions of dollars per day in lost production. This is why there is so much concern with regards to ‘over inspecting’ and ‘under inspecting’ pressure equipment.

Comments and Discussion

Add a Comment

Please log in or register to participate in comments and discussions.